Composite Cables |

|||

|

| Conductor | Stranded annealed tinned copper wire, 30AWG(7/38AWG) |

| Insulation | S.S. cell. Thickness 0.505mm. Outer diameter 1.3+0.07mm |

| Shield | Tinned copper braid, 0.1mm, 90% coverage |

| Sheath | PVC, Thickness 0.219mm. Outer diameter 2.15mm |

| Sheath Color | Green/Blue/Red |

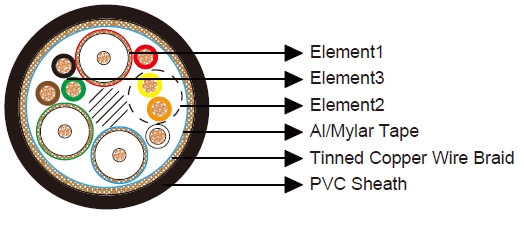

Element 2: 1PRx28AWG(7/36AWG) Stranded TC/Foam PE+Skin

| Conductor | Stranded annealed tinned copper wire, 7/36AWG |

| Insulation | High density polyethylene. Thickness 0.15mm. Outer diameter 0.7+0.05mm |

| Insulation Color | Yellow and orange |

| Twisting | The cores shall twisted together in pair, the lay between each twist shall not exceed 100 mm. Outer diameter 1.4mm |

Element 3: 5Cx28AWG(7/36AWG) Stranded TC/PE

| Conductor | Stranded annealed tinned copper wire, 7/36AWG |

| Insulation | High density polyethylene. Thickness 0.15mm. Outer diameter 0.7+0.03mm |

| Insulation Color | Red/Purple/White |

Element Assembly

| Overall Screen | Aluminum/ mylar tape |

| Braid Shield | Braid of tinned copper wire. Coverage ≥ 85% |

| Outer Sheath | LSFROH elastomeric sheath,Thickness 0.87mm. Outer diameter 7.3 +0.2mm, other materail is optional |

| Sheath Color | Black or as per the client’s requirement |

Physical Properties:

Temperature rating: -25°C to +80°C

Minimum bending radius:3 x Overall Diameter

Electrical Properties:

Rated voltage: 30V

Max conductor resistance at 20°C: ≤237 Ohm/Km Min insulation resistance: ≥100M Ohm/m

Spark test: Min. AC 500V/0.15second Nom. differential impedance: 100+15 Ohm Mutual capacitance: 46pF/m

Fire Performance in General:

Vertical flame propagation for a single insulated wire or cable

EN 50265-2-1; IEC 60332-1-2; NF C 32-070 2.1 (C2)

Vertical flame spread of vertically mounted bunched wires or cables

EN 50266-2-4 + EN 50305; IEC 60332-3-24; NF C 32-070 2.2 (C1); VDE 0472 Teil 804

Low Smoke Emission

EN 50268-2; IEC 61034-2; NF C 32-073 ;NF C 20-902; NF F 16 101; VDE 0472 Teil 816

Halogen Free

EN 50267-2-1; IEC 60754-1; NF C 32-074; NF C 20-454; VDE 0472 Teil 815

Low Corrosivity (Acidity & Conductivity)

EN 50267-2-2/3; IEC 60754-2; NF C 32-074; NF C 20-453; VDE 0472 Teil 813

Low Toxicity

EN 50305; NF X 70-100; NF F 63 808; TM1-04; BS6853

Smoke Index

NF F 63 808; BS6853; NF F 16 101

Fire Performance Relating to Rolling Stock Application:

DIN 5510-2

BS 6853

NF F16 101

NF F 63 808