Composite Cables |

|||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Conductor | 7/0.67mm Stranded bare copper wire |

| Insulation | XLPE compound. Nominal outer diameter 3.41mm |

| Insulation Color | Blue, Brown and Green/Yellow |

6 Core Central Loose Tube Fiber Optic Cable

| Optical Fiber | Single-mode cabled fibers meet or exceed the requirements of ITUT G.652.D specification |

| Loose Tube | PBT tubes1.80±0.1mm outer diameter, contains 6 fibers, The tubes are filled with a thixotropic gel to prevent the ingress of water |

| Fiber Glass Yarn | Fiber Glass Yarn is laid over the tube core to serve as peripheral strength member. |

| Sheath | PE outer Sheathis extruded over the glass yarn, Nominal outer diameter is about 3.40mm |

| Sheath Color | Black |

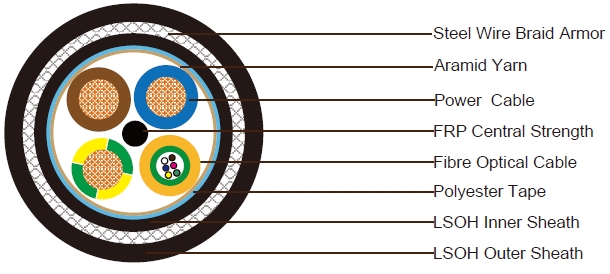

Element Assembly

| Central Strength Member | 1.5mm FRP central strength member with PE/PVC coating if necessary |

| Strength member | Aramid yarn helically is applied over cable core. |

| Inner Jacket | BlackPE, thickness 1.00mm |

| Armor | Steel wire braid, coverage 80%, 0.25mm steel tape armor is optional |

| Sheath | PE, thickness 1.80mm, nominal outer diameter 16.00±1.0mm |

| Sheath Color | Black |

Optical Characteristics

Single-mode fibers meet or exceed the requirements of ITUT G.652.D, as listed in below:

| Parameter | Standard Single Mode Fiber per ITU-T G.652D | Non-zero Dispersion Shifted fiber per ITU-T G.655 | Non-zero Dispersion Shifted fiber per ITU-T G.656 | Units | |

| Fiber Code | 9 | 8 | 7 | ||

| Attenuation, Loose Tube Cables | @1310nm | ≤0.35 | N/A | N/A | dB/km |

| @1550nm | ≤0.22 | ≤0.22 | ≤0.22 | dB/km | |

| @1625nm | ≤0.25 | ≤0.26 | ≤0.26 | dB/km | |

| Attenuation, Tight Buffer or Semi-Tight Cables | @1310nm | ≤0.38 | N/A | dB/km | |

| @1550nm | ≤0.28 | N/A | dB/km | ||

| Chromatic Dispersion | between 1260 and 1360nm (O Band) | ≤3.5 | N/A | N/A | ps/(nm*km) |

| between 1460 and 1530nm (S Band) | N/A | N/A | 2.0-7.0 | ps/(nm*km) | |

| between 1530 and 1565nm (C Band) | ≤18 | 1.0-10.0 | 7.0-10.0 | ps/(nm*km) | |

| between 1565 and 1625nm (L Band) | ≤22 | 7.0-12.0 | 10.0-14.0 | ps/(nm*km) | |

| Zero Dispersion Wavelength | 1310±11 | 1530-1560 | 1460-1565 | nm | |

| Zero Dispersion Slope | 0.093 | 0.093 | 0.093 | ps/(nm2. km) | |

| Point Discontinuity at 1300nm& 1550nm | 0.1 | 0.1 | 0.1 | dB | |

| Mode Field Diameter | @1300nm | 9.3±0.5 | N/A | N/A | um |

| @1550nm | 10.4±0.8 | 8.5±0.6 | 9.0±0.5 | um | |

| Cable Cut-off Wavelength | ≤1260 | ≤1450 | ≤1450 | nm |

| PMD (Individual fiber) | ≤0.2 | ≤0.2 | ≤0.2 | ps/km1/2 |

| Cladding Diameter | 125±1 | 125±1 | 125±1 | um |

| Core/Cladding Concentricity Error | ≤0.5 | ≤0.5 | ≤0.6 | um |

| Cladding Non-Circularity | ≤1.0 | ≤1.0 | ≤1.0 | % |

| Coating Non-Circularity | ≤6.0 | ≤6.0 | ≤6.0 | % |

| Primary Coating Diameter | 245±10 | 245±10 | 245±10 | um |

| Proof-Test Level | 100 (0.7) | 100 (0.7) | 100 (0.7) | Kpsi/GN/m2 |

| Fatigue Coefficient | ≥20 | ≥20 | ≥20 | |

| Temperature Dependence between 0°C ~ +70°C @ 1310& 1550nm | 0.1 | 0.1 | 0.1 | Db/km |

The fibers contain no splices.

Mechanical Properties:

Minimum Bending Radius:

Under Installation: 25×OD

During Operation: 12.5×OD

Temperature Range:

Operating Temperature Range: -40°C (-40 oF to +70°C (+158 oF)

StorageTemperature Range: -50°C (-58 oF to +70°C (+158 oF)

Maximum Crush Resistance:

Long Term:300N

Short Term:10000N

Minimum Tensile Resistance:

Under Installation: 1500N

During Operation: 600N.

Repeated Impact: 4.0 N.m (J

Twist (Torsion): 180x10 times, 125xOD

Cyclic Flexing: 25 cycles for armoured cables;