| FIREGUARD Flame Retardant Cables | |||

![]() Flame Retardant Power & Control Cables

Flame Retardant Power & Control Cables

300/500V XLPE Insulated, PVC Sheathed, Screened Power Cables (Multicore)FGD200 05ROV-R (CU/XLPE/OSCR/PVC 300/500V Class 2) |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flame Retardance (Single Vertical |

EN 60332-1-2; IEC 60332-1-2; BS EN 60332-1-2; VDE |

Reduced Fire Propagation |

EN 60332-3-24 (cat. C); IEC 60332-3-24; BS EN 60332-3-24; VDE 0482-332-3; NBN C 30-004 (cat. F2); NF C32-070-2.2(C1); CEI 20-22/3-4; EN 50266-2-4*; DIN VDE 0482-266-2-4 |

Note: Asterisk ** denotes that the standard compliance is optional, depending on the oxygen index of the PVC

compound and the cable design.

VOLTAGE RATING

300/500V

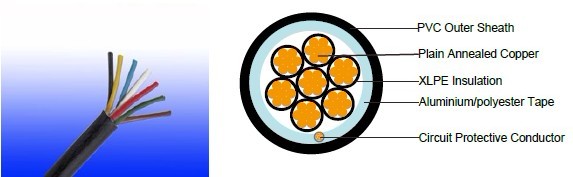

CABLE CONSTRUCTION

Conductor: Plain annealed copper wire, stranded according to IEC(EN) 60228 class 2.

Insulation: Extruded cross-linked XLPE compound.

Filler, binder(if any): PP, Mylar tape

Circuit Protective Conductor: Annealed plain copper (class 2)

Overall Screen: Aluminium/polyester tape

Outer Sheath: Thermoplastic PVC compound. UV resistance, hydrocarbon resistance, oil resistance,

anti rodent and anti termite properties can be offered as option. Compliance to fire performance

standard (IEC 60332-1, IEC 60332-3, UL 1581, UL 1666 etc) depends on the oxygen index of the

PVC compound and the overall cable design. LSPVC can also be provided upon request.

COLOUR CODE

Insulation Colour as per BS7671

|

With Earth Conductor |

Without Earth Conductor |

2Cores |

- |

Brown, Blue |

3Cores |

Yellow/Green, Brown, Blue |

Brown, Gray, Black |

4Cores |

Yellow/Green, Brown, Gray, Black |

Brown, Gray, Black, Blue |

5Cores |

Yellow/Green, Brown, Gray, Black, Blue |

Brown, Gray, Black, Blue, Black |

Above 5 Cores |

Yellow/Green, Black Numbered |

Black Numbered |

Sheath Colour: Black (other colors upon request)

Physical AND THERMAL PROPERTIES

Temperature range during operation: Max.90°C for XLPE

250°C in short-circuit for 5secs max.

Minimum bending radius: 6 x Overall Diameter

CONSTRUCTION PARAMETERS

| Conductor | FGD200 05ROV-R | |||||||

| No. of Core X Cross Section |

No./Nominal Diameter of Strands |

Nominal Overall Diameter Conductor |

Nominal Insulation Thickness |

Cross- Section Area Of Circuit Protective Conductor |

Nominal Sheath Thickness |

Nominal Overall Diameter |

Max.Dc Resistance Of Conductor @20°C |

Approx. Weight |

Noxmm2 |

No./mm |

mm |

mm |

mm2 |

mm |

mm |

Ω/km |

kg/km |

7x1.0 |

7i0.44 |

1.32 |

0.6 |

1.0 |

1.0 |

11.2 |

18.1 |

186 |

7x1.5 |

7i0.53 |

1.59 |

0.7 |

1.5 |

1.1 |

12.9 |

12.1 |

253 |

7x2.5 |

7i0.67 |

2.01 |

0.8 |

2.5 |

1.2 |

14.9 |

7.41 |

365 |

12x1.5 |

7i0.53 |

1.59 |

0.7 |

1.5 |

1.2 |

16.8 |

12.1 |

404 |

12x2.5 |

7i0.67 |

2.01 |

0.8 |

2.5 |

1.4 |

19.8 |

7.41 |

595 |

19x1.5 |

7i0.53 |

1.59 |

0.7 |

1.5 |

1.3 |

19.7 |

12.1 |

600 |

19x2.5 |

7i0.67 |

2.01 |

0.8 |

2.5 |

1.5 |

23.2 |

7.41 |

885 |

Electrical Properties

Conductor Operating Temperature : 90°C

Ambient Temperature : 30°C

Current-Carrying Capacities (Amp)

Conductor cross- sectional area |

Reference Method |

Reference Method 3 (enclosed in conduit on |

Reference Method |

Reference Method 11 (on a perforated cable tray, horizontal or vertical) |

Reference Method 12 (free air) |

||||||

Horizontal flat spaced |

Vertical flat spaced |

Trefoil |

|||||||||

|

2 cables, single- phase a.c. or d.c. |

3 or 4 cables, |

2 cables, single- phase a.c. or d.c |

3 or 4 cables, |

2 cables, single- phase a.c. or d.c. flat and touching |

3 or 4 cables, |

2 cables, single- phase a.c. or d.c. or flat and touching |

3 or 4 cables, |

2 cables, single- phase a.c. or d.c. |

2 |

3 cables, trefoil |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

mm2 |

A |

A |

A |

A |

A |

A |

A |

A |

A |

A |

A |

1.5 |

18 |

17 |

22 |

19 |

25 |

23 |

- |

- |

- |

- |

- |

2.5 |

24 |

23 |

30 |

26 |

34 |

31 |

- |

- |

- |

- |

- |

Voltage Drop (Per Amp Per Meter)

| Nominal Cross Section Area |

2 cables d.c. |

2 cables, single-phase a.c. | 3 or 4 cables, 3-phase a.c. | |||

| Ref. Methods 3 and 4 (enclosed in conduit etc, in or on a wall) |

Ref. Methods 1 and 11 (clipped direct or on trays touching) |

Ref. Methods 3 and 4 (enclosed in conduit etc, in or on a wall) |

Ref. Methods 1, 11 and 12 (in trefoil) |

Ref. Methods 1 and 11(Flat and touching) |

||

1 |

2 |

3 |

4 |

5 |

6 |

7 |

mm2 |

mV/A/m |

mV/A/m |

mV/A/m |

mV/A/m |

mV/A/m |

mV/A/m |

1.5 |

31 |

31 |

27 |

27 |

27 |

27 |

2.5 |

19 |

19 |

16 |

16 |

16 |

16 |