| Rolling Stock Cables | |||||||||||||||

|

|||||||||||||||

![]() Category 5E Data Cables

Category 5E Data Cables

FRL-Cat5E-4C0.5S, FRL-Cat5E-4C22A, FRL-Cat5E-4P22A

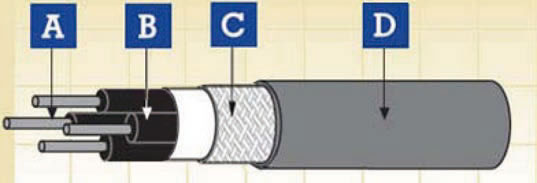

A. Conductor B. Insulation C. Screen D. Sheath

Application

The cables are designed for permanently protected installation, inside and outside railway rolling stock, buses and other vehicles to connect fixed parts. Ethernet based networks as: infotainment, multimedia, passenger information system etc.

Construction

For 4 x 0.5mm2, 4 x 22AWG cables

Conductors: Stranded tin plated copper conductor (for 0.5mm2 cables) or stranded silver plated copper conductor (for 22AWG cables) according to IEC 60228 class 5.

Insulation:Electron beam crosslinkable compound.

Cable Element: Individual conductor stranded together

EMC Screen1:Plastic laminated aluminium-tape.

EMC Screen2:Tin plated copper braid

Core Wrapping:Plastic tape(s).

Outer Sheath:Electron beam crosslinkable compound.

For 4 x 2 x 22AWG cables

Center: PE filler.

4 pairs 2 x 22AWG: Stranded tin plated copper conductor according to IEC 60228 class 5

Insulation:Electron beam crosslinkable compound.

EMC Screen1:Plastic laminated aluminium-tape.

EMC Screen2:Tin plated copper braid

Core Wrapping:Plastic tape(s).

Outer Sheath:Electron beam crosslinkable compound.

Electrical & Mechanical Properties

| Nominal Voltage | 300V |

| Maximum Conductor Temperature | 90℃ |

| Minimum Permissible Ambient Temperature | -40°C |

| Bending Radius | 6 x Overall Diameter |

Chemical & Environmental Properties

| EN 60684-2 | No fluorine |

| EN 50305; EN 60811-2-1 | Resistance to mineral oil & fuel oil, acid & alkali |

| EN 50305 | Resistance to ozone |

Fire Performance for rolling stock application

| EN 50306-2 | Hazard levels HL1, HL2/HL3, HL4 |

| DIN 5510-2 | Protection level 1/2/3/4 |

| BS 6853 | Interior use 1a, 1b, II; Exterior use 1a, 1b, II |

| NF F 16-101 | FO |

Fire Performance in general

| EN 50265-2-1; IEC 60332-1-2; NF C 32-070 2.1 (C2) | Vertical flame propogation for a single insulated wire or cable |

| EN 50266-2-4 + EN 50305; IEC 60332-3-24; NF C 32-070 2.2 (C1); VDE 0472 Teil 804 |

Vertical flame spread of vertically mounted bunched wires or cables |

| EN 50268-2; IEC 61034-2; NF C 32-073 ; NF C 20-902; NF F 16 101; VDE 0472 Teil 816 |

Low Smoke Emission |

| EN 50267-2-1; IEC 60754-1; NF C 32-074;NF C 20-454; VDE 0472 Teil 815 | Halogen Free |

| EN 50267-2-2/3; IEC 60754-2; NF C 32-074;NF C 20-453; VDE 0472 Teil 813 | Low Corrosivity (Acidity & Conductivity) |

| EN 50305; NFX 70-100; NFF 63808; TM1-04; BS6853 | Low Toxicity |

| NFF 16101; NFF 63808; BS6853 | Smoke index |

FRL-Cat5E-4C0.5S

Nominal Cross Sectional Area |

Nominal Sheath Thickness |

Nominal Overall Diameter |

Nominal Weight |

Maximum Conductor Resistance 20°C |

Maximum Resistance Unbalance |

Characteristic Impedance | Transfer Impedance |

Maximum Capacitance |

|

| @100MHz | f≤30MHz |

core to core |

Core to screen | ||||||

mm2 |

mm |

mm |

kg/km |

Ω/km |

Ω/km |

Ω | mΩ/m |

pF/m |

pF/m |

0.5 |

1.2 |

8.3 |

102 |

40.1 |

1.1 |

100+/-5 | 200 |

65 |

100 |

FRL-Cat5E-4C22A

Nominal Cross Sectional Area |

Nominal Sheath Thickness |

Nominal Overall Diameter |

Nominal Weight |

Maximum Conductor Resistance 20°C |

Maximum Resistance Unbalance |

Characteristic Impedance |

Transfer Impedance |

Maximum Capacitance |

|

@100MHz |

f≤30MHz |

core to core |

Core to screen | ||||||

AWG |

mm |

mm |

kg/km |

Ω/km |

Ω/km |

Ω |

mΩ/m |

pF/m |

pF/m |

22 |

1.2 |

7.25 |

81 |

54.4 |

1.1 |

100+/-5 |

200 |

65 |

100 |

FRL-Cat5E-4P22A

Nominal Cross Sectional Area |

Nominal Sheath Thickness |

Nominal Overall Diameter |

Nominal Weight |

Maximum Conductor Resistance 20°C |

Maximum Resistance Unbalance |

Characteristic Impedance |

Transfer Impedance |

Maximum Capacitance |

|

@100MHz |

f≤30MHz |

core to core |

Core to screen | ||||||

AWG |

mm |

mm |

kg/km |

Ω/km |

Ω/km |

Ω |

mΩ/m |

pF/m |

pF/m |

22 |

1.2 |

12.6 |

174 |

54.4 |

1.1 |

100+/-5 |

200 |

65 |

100 |