| Industrial Cables | |||

Industrial Cables Multi-Core Flexible Cables

Industrial Cables Multi-Core Flexible Cables

318B to BS 6500

Application and Description

318B to BS 6500 cables may be used as an indoor general wiring cable primarily for installations in public areas.

Examples include use on pendant lighting drops or as a general supply lead within hospital or airport

projects. They are suitable for installations where fire, smoke emission and toxic fumes create a

potential threat to life and equipment. 318B is equivalent to harmonized code H05Z1Z1-F.

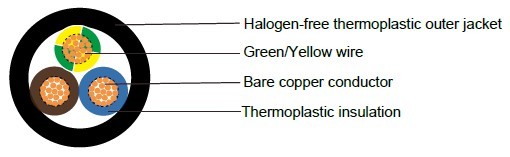

Cable Construction

Fine bare copper strands

Stranding to BS 6360 Class 5 or IEC 60228 Class 5

Halogen-fee thermoplastic TI6 core insulation

Green/Yellow grounding (3 conductors and above)

Halogen-fee thermoplastic TM7 outer jacket

Core Identification

2 Cores: Brown, Blue

3 Cores: Brown, Blue and Green/Yellow

4 Cores: Brown, Grey, Black and Green/Yellow

5 Cores: Brown, Blue, Grey, Black and Green/Yellow

Technical Characteristics

Working voltage: 300/500 volts

Test voltage: 2500 volts

Flexing bending radius: 6xOverall diameter

Fixed bending radius: 4xOverall diameter

Operating temperature: -30º C to +90º C

Short circuit temperature: +160º C

Insulation resistance: 20 MΩxkm

Halogen free acc. to EN 50267-2-1 / IEC 60754-1

Smoke density acc. to EN 50268-2 / IEC 61034-2

Corrosivity of gases acc. to EN 50267-2-2, IEC 60754-2

Flame retardancy acc. to EN 50265-2-1, IEC 60332-1

Cable Parameter

| AWG (No of Strands/ Strand Diameter) |

No. of Cores x Nominal Cross Sectional Area #xmm² |

Nominal Thickness of Insulation mm |

Nominal Thickness of Sheath mm |

Nominal Overall Diameter mm |

Nominal Copper Weight kg/km | Nominal Weight kg/km |

| 3182B | ||||||

| 18(24/32) | 2x0.75 | 0.6 | 0.8 | 6.2 | 14.4 | 58 |

| 17(32/32) | 2x1 | 0.6 | 0.8 | 6.6 | 19 | 67 |

| 16(30/30) | 2x1.5 | 0.7 | 0.8 | 7.4 | 29 | 87 |

| 14(50/30) | 2x2.5 | 0.8 | 1.0 | 9.3 | 48 | 138 |

| 12(56/28) | 2x4 | 0.8 | 1.1 | 10.6 | 76.8 | 190 |

| 3183B | ||||||

| 18(24/32) | 3x0.75 | 0.6 | 0.8 | 6.6 | 21.6 | 68 |

| 17(32/32) | 3x1 | 0.6 | 0.8 | 6.9 | 29 | 81 |

| 16(30/30) | 3x1.5 | 0.7 | 0.9 | 8.1 | 43 | 109 |

| 14(50/30) | 3x2.5 | 0.8 | 1.1 | 10.1 | 72 | 172 |

| 12(56/28) | 3x4 | 0.8 | 1.2 | 11.5 | 115.2 | 242 |

| 3184B | ||||||

| 18(24/32) | 4x0.75 | 0.6 | 0.8 | 7.1 | 29 | 81 |

| 17(32/32) | 4x1 | 0.6 | 0.9 | 7.7 | 38 | 101 |

| 16(30/30) | 4x1.5 | 0.7 | 1.0 | 9 | 58 | 117 |

| 14(50/30) | 4x2.5 | 0.8 | 1.1 | 11 | 96 | 210 |

| 12(56/28) | 4x4 | 0.8 | 1.4 | 12.5 | 153.6 | 298 |

| 3185B | ||||||

| 18(24/32) | 5x0.75 | 0.6 | 0.9 | 8 | 36 | 102 |

| 17(32/32) | 5x1 | 0.6 | 0.9 | 8.4 | 48 | 107 |

| 16(30/30) | 5x1.5 | 0.7 | 1.1 | 10 | 72 | 169 |

| 14(50/30) | 5x2.5 | 0.8 | 1.2 | 12.3 | 120 | 260 |

| 12(56/28) | 5x4 | 0.8 | 1.4 | 14.1 | 192 | 371 |