| Industrial Cables | |||

Australian Standard (Medium Voltage)

Australian Standard (Medium Voltage)

6.35/11kV Three Core Individual Screened & PVC Sheathed (Al Conductor)

Application

6.35/11kV Three Core Individual Screened & PVC Sheathed (Al Conductor) cables are designed to be used for the supply of electrical energy in fixed applications up to the rated voltages at a nominal power frequency between 49Hz and 61Hz., 6.35/11kV Three Core Individual Screened & PVC Sheathed (Al Conductor) cables are suitable for use in distribution installation, electrical power station , they are applied for installation, outdoors, underground where subject to mechanical damage.

Standard

AS/NZS 1429.1

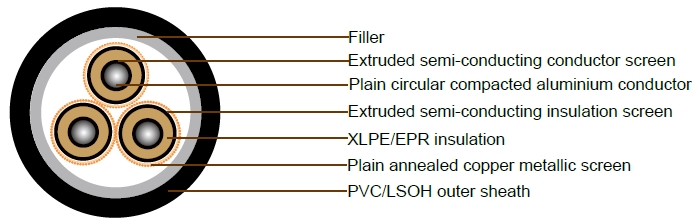

Cable Construction

CONDUCTOR: Plain circular compacted aluminium to AS/NZS1125 Maximum Continuous Operating Temperature: 90°C

CONDUCTOR SCREEN: Extruded semiconducting compound, bonded to the insulation and applied in the same operation as the insulation

INSULATION: Cross Linked Polyethylene (XLPE) – standard Ethylene Propylene Rubber (EPR) – alternative

INSULATION SCREEN: Extruded semiconducting compound

METALLIC SCREEN: Plain annealed copper wire: 3kA for nominal 1 second(LIGHT DUTY) Plain annealed copper wire: 10kA for nominal 1 second(HEAVY DUTY)

SHEATH: Black 5V90 polyvinyl chloride (PVC) – standard

Orange 5V90 PVC inner plus black high density polyethylene (HDPE) outer – alternative Low smoke zero halogen (LSOH) – alternative

Technical Characteristics

LIGHT DUTY

| Nominal conductor area | Maximum Conductor DC resistance at 20°C | Cond. AC resistance at 50Hz and 90°C | Inductive reactance at 50Hz | Insulation resistance at 20°C | Conductor to screen capacitance | Maximum diaelectric stress | Current Ratings | ||

| Unenclosed In Air | Unenclosed In Air | Unenclosed In Air | |||||||

| mm2 | Ohm/km | Ohm/km | Ohm/km | MegOhm.km | µF x km | kV x mm | A | A | A |

| 35 | 0.868 | 1.11 | 0.127 | 11000 | 0.22 | 2.54 | 136 | 133 | 111 |

| 50 | 0.641 | 0.821 | 0.121 | 9900 | 0.243 | 2.46 | 162 | 157 | 130 |

| 70 | 0.443 | 0.569 | 0.112 | 8700 | 0.276 | 2.37 | 201 | 191 | 160 |

| 95 | 0.32 | 0.41 | 0.106 | 7800 | 0.311 | 2.3 | 244 | 228 | 191 |

| 120 | 0.253 | 0.325 | 0.103 | 7100 | 0.339 | 2.25 | 280 | 259 | 220 |

| 150 | 0.206 | 0.265 | 0.0996 | 6600 | 0.368 | 2.22 | 317 | 290 | 246 |

| 185 | 0.164 | 0.211 | 0.0968 | 6100 | 0.398 | 2.18 | 363 | 328 | 279 |

| 240 | 0.125 | 0.161 | 0.0933 | 5400 | 0.445 | 2.14 | 426 | 379 | 323 |

| 300 | 0.1 | 0.13 | 0.091 | 4900 | 0.491 | 2.11 | 486 | 427 | 370 |

| 400 | 0.0778 | 0.102 | 0.0876 | 4400 | 0.548 | 2.08 | 562 | 487 | 423 |

Cable Parameter

LIGHT DUTY

| Sectional Area of Conductor | Nom. Conductor Diameter | Nom. Insulation Thickness | Nom. Diamete Over insulation | Screen Area on Each core | No. and Diamter of Screened Wires | Nom. Diamete Over Screened Wires | Nom. Overall Diameter | Approx. mass |

| mm2 | mm | mm | mm | mm2 | no x mm | mm | mm | kg/100m |

| 35 | 6.9 | 3.4 | 14.9 | 6.8 | 12 x 0.85 | 16.3 | 43.9 | 153 |

| 50 | 8.1 | 3.4 | 16 | 6.8 | 12 x 0.85 | 17.5 | 46.7 | 175 |

| 70 | 9.6 | 3.4 | 17.6 | 7.4 | 13 x 0.85 | 19.0 | 50.4 | 211 |

| 95 | 11.4 | 3.4 | 19.3 | 7.9 | 14 x 0.85 | 20.7 | 54.2 | 251 |

| 120 | 12.8 | 3.4 | 20.7 | 8.5 | 15 x 0.85 | 22.1 | 57.5 | 289 |

| 150 | 14.2 | 3.4 | 22.1 | 8.5 | 15 x 0.85 | 23.5 | 60.7 | 326 |

| 185 | 15.7 | 3.4 | 23.6 | 9.6 | 17 x 0.85 | 25.2 | 64.6 | 379 |

| 240 | 18 | 3.4 | 25.9 | 10.2 | 18 x 0.85 | 27.6 | 70.2 | 459 |

| 300 | 20.1 | 3.4 | 28.3 | 10.8 | 19 x 0.85 | 29.6 | 74.7 | 535 |

| 400 | 23 | 3.4 | 31.1 | 11.9 | 21 x 0.85 | 32.7 | 82.3 | 655 |

Technical Characteristics

HEAVY DUTY

| Nominal conductor area | Maximum Conductor DC resistance at 20°C | Cond. AC resistance at 50Hz and 90°C | Inductive reactance at 50Hz | Insulation resistance at 20°C | Conductor to screen capacitance | Maximum diaelectric stress | Current Ratings | ||

| Unenclosed In Air | Unenclosed In Air | Unenclosed In Air | |||||||

| mm2 | Ohm/km | Ohm/km | Ohm/km | MegOhm.km | µF x km | kV x mm | A | A | A |

| 35 | 0.868 | 1.11 | 0.127 | 11000 | 0.22 | 2.54 | 136 | 133 | 111 |

| 50 | 0.641 | 0.821 | 0.121 | 9900 | 0.243 | 2.46 | 162 | 157 | 130 |

| 70 | 0.443 | 0.569 | 0.112 | 8700 | 0.276 | 2.37 | 201 | 191 | 160 |

| 95 | 0.32 | 0.41 | 0.106 | 7800 | 0.311 | 2.3 | 244 | 228 | 191 |

| 120 | 0.253 | 0.325 | 0.103 | 7100 | 0.339 | 2.25 | 280 | 259 | 220 |

| 150 | 0.206 | 0.265 | 0.0996 | 6600 | 0.368 | 2.22 | 317 | 290 | 246 |

| 185 | 0.164 | 0.211 | 0.0968 | 6100 | 0.398 | 2.18 | 363 | 328 | 279 |

| 240 | 0.125 | 0.161 | 0.0933 | 5400 | 0.445 | 2.14 | 426 | 379 | 323 |

| 300 | 0.1 | 0.13 | 0.091 | 4900 | 0.491 | 2.11 | 486 | 427 | 370 |

| 400 | 0.0778 | 0.102 | 0.0876 | 4400 | 0.548 | 2.08 | 562 | 487 | 423 |

Cable Parameter

HEAVY DUTY

| Sectional Area of Conductor | Nom. Conductor Diameter | Nom. Insulation Thickness | Nom. Diamete Over insulation | Screen Area on Each core | No. and Diamter of Screened Wires | Nom. Diamete Over Screened Wires | Nom. Overall Diameter | Approx. mass |

| mm2 | mm | mm | mm | mm2 | no x mm | mm | mm | kg/100m |

| 35 | 6.9 | 3.4 | 14.9 | 7.9 | 14 x 0.85 | 18.2 | 44.6 | 165 |

| 50 | 8.1 | 3.4 | 16 | 10.8 | 19 x 0.85 | 19.3 | 47.5 | 195 |

| 70 | 9.6 | 3.4 | 17.6 | 15.3 | 27 x 0.85 | 20.9 | 51.1 | 245 |

| 95 | 11.4 | 3.4 | 19.3 | 20.4 | 36 x 0.85 | 22.6 | 55 | 295 |

| 120 | 12.8 | 3.4 | 20.7 | 22.7 | 40 x 0.85 | 24 | 58.2 | 340 |

| 150 | 14.2 | 3.4 | 22.1 | 22.7 | 40 x 0.85 | 25.4 | 61.5 | 375 |

| 185 | 15.7 | 3.4 | 23.6 | 22.7 | 40 x 0.85 | 26.9 | 64.9 | 420 |

| 240 | 18 | 3.4 | 25.9 | 22.7 | 40 x 0.85 | 29.2 | 70.3 | 490 |

| 300 | 20.1 | 3.4 | 28.3 | 22.7 | 40 x 0.85 | 31.6 | 75.5 | 570 |

| 400 | 23 | 3.4 | 31.1 | 22.7 | 40 x 0.85 | 34.6 | 82.8 | 690 |