| Industrial Cables | |||

Industrial Cables

Industrial Cables

H05V-K UL/H07V-K UL-UL/CSA/HAR/MTW&UL1015 PVC

Application and Description

H05VK UL / H07V-K UL are internationally approved harmonized, UL/CSA and AWM/MTW approved PVC

European flexible single-conductor wires. Can be found in appliance wiring and machine tool wiring as well

as in control systems. They may also be used in pipes and flexible conduits. Recommended for the internal

wiring of apparatus, switchboards and distributor boards in electronic and electrical equipment designed for

international use in North American & European countries and for MRO replacement of international made

equipment wire.

Standard and Approval

<HAR> HD 21.7 S2, VDE-0281 Part-3,UL-Standard and Approval 1063 MTW, UL-AWM Style 1015, CSA

TEW, CSA-AWM I A/B, FT-1, CE Low Voltage Directive 73/23/EEC and 93/68/EEC, ROHS compliant

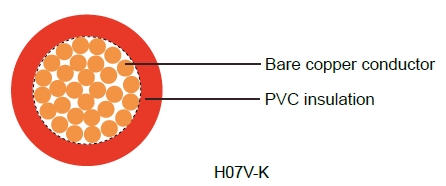

Cable Construction

Fine tinned copper strands

Strands to VDE-0295 Class-5, IEC 60228 Class-5, HD383 Class-5

Special PVC TI3 core insulation

Cores to VDE-0293 colors

H05V-K UL (22, 20 & 18 AWG)

H07V-K UL (16 AWG and Larger)

X05V-K UL & X07V-K UL for non-HAR colors

Technical Characteristics

Working voltage: 300/500v (H05V-K UL)

Working voltage: 450/750v (H07V-K UL)

Working voltage UL/CSA: 600v AC, 750v DC.

Test voltage: 2500 volts

Flexing/Static bending radius: 10-15 x Ø

Temperature HAR/IEC: -40º to +70º C

Temperature UL-AWM: -40º to +105º C

Temperature UL-MTW: -40º C to +90º C

Temperature CSA-TEW: -40º C to +105º C

Flame retardant: IEC 60332.1, FT-1

Insulation resistance: 20 MΩ x km

Cable Parameter

AWG |

No. of Cores x Nominal Cross Sectional Area # x mm² |

Nominal Thickness of Insulation mm |

Nominal Overall Diameter mm |

Nominal Copper Weight kg/Km |

Nominal Weight kg/Km |

20(16/32) |

1 x 0.5 |

0.6 |

2.5 |

4.9 |

11 |

18(24/32) |

1 x 0.75 |

0.6 |

2.7 |

7.2 |

14 |

17(32/32) |

1 x 1 |

0.6 |

2.9 |

9.6 |

17 |

16(30/30) |

1 x 1.5 |

0,7 |

3.1 |

14.4 |

20 |

14(50/30) |

1 x 2.5 |

0,8 |

3.7 |

24.0 |

32 |

12(56/28) |

1 x 4 |

0,8 |

4.4 |

38.0 |

45 |

10(84/28) |

1 x 6 |

0,8 |

4.9 |

58.0 |

63 |

8(80/26) |

1 x 10 |

1,0 |

6.8 |

96.0 |

120 |

6(128/26) |

1 x 16 |

1,0 |

8.9 |

154.0 |

186 |

4 (200/26) |

1 x 25 |

1,2 |

10.1 |

240 |

261 |

2 (280/26) |

1 x 35 |

1,2 |

11.4 |

336 |

362 |

1 (400/26) |

1 x 50 |

1,4 |

14.1 |

480 |

539 |

2/0 (356/24) |

1 x 70 |

1,4 |

15.8 |

672 |

740 |

3/0 (485/24) |

1 x 95 |

1,6 |

18.1 |

912 |

936 |

4/0 (614/24) |

1 x 120 |

1,6 |

19.5 |

1152 |

1184 |