| Industrial Cables | |||

Industrial Cables

Industrial Cables

H05V2-K/H07V2-K

Application and Description

H05V2-K/H07V2-K special heat-resistant flexible single-conductor hook-up wires are ideal for use in power current

installation, switch cabinets, motors and transformers which are subject to direct contact with high

temperature (e.g. varnishing machines and drying towers etc.). H05V2-K/H07V2-K cables are also suitable for inside wiring of

electrical equipments such as lighting and heating apparatus.

Standard and Approval

<HAR> HD 21.7 S2, CEI 20-20, CEI20-52, VDE-0281 Part-7,

CE Low Voltage Directive 73/23/EEC and 93/68/EEC,ROHS compliant

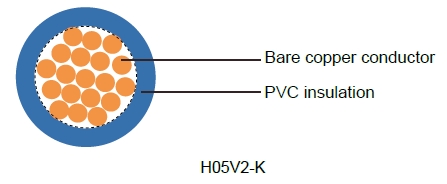

Cable Construction

Fine bare copper strands

Strands to VDE-0295 Class-5, IEC 60228 Class-5, BS 6360 cl. 5 and HD 383

Special heat resistant PVC TI3 core insulation to DIN VDE 0281 part 7

Cores to VDE-0293 colors

H05V2-K (20, 18 & 17 AWG)

H07V2-K (16 AWG and Larger)

Technical Characteristics

Working voltage: 300/500v (H05V2-K)/ 450/750v (H07V2-K)

Working voltage: Test voltage: 2000 volts

Flexing bending radius: 10-15 x Ø

Static bending radius: 10-15 x Ø

Flexing temperature: +5º C to +90º C

Static temperature: -10º C to +105º C

-Short circuit temperature: +160º C

Flame retardant: IEC 60332.1

Insulation resistance: 20 MΩ x km

Cable Parameter

AWG |

No. of Cores x Nominal Cross Sectional Area # x mm² |

Nominal Thickness of Insulation mm |

Nominal Overall Diameter mm |

Nominal Copper Weight kg/Km |

Nominal Weight kg/Km |

H05V2-K |

|||||

20(16/32) |

1 x 0.5 |

0.6 |

2.5 |

4.8 |

8.7 |

18(24/32) |

1 x 0.75 |

0.6 |

2.7 |

7.2 |

11.9 |

17(32/32) |

1 x 1 |

0.6 |

2.8 |

9.6 |

14.0 |

H07V2-K |

|||||

16(30/30) |

1 x 1.5 |

0,7 |

3.4 |

14.4 |

20 |

14(50/30) |

1 x 2.5 |

0,8 |

4.1 |

24 |

33.3 |

12(56/28) |

1 x 4 |

0,8 |

4.8 |

38 |

48.3 |

10(84/28) |

1 x 6 |

0,8 |

5.3 |

58 |

68.5 |

8(80/26) |

1 x 10 |

1,0 |

6.8 |

96 |

115 |

6(128/26) |

1 x 16 |

1,0 |

8.1 |

154 |

170 |

4 (200/26) |

1 x 25 |

1,2 |

10.2 |

240 |

270 |

2 (280/26) |

1 x 35 |

1,2 |

11.7 |

336 |

367 |

1 (400/26) |

1 x 50 |

1,4 |

13.9 |

480 |

520 |

2/0 (356/24) |

1 x 70 |

1,4 |

16 |

672 |

729 |

3/0 (485/24) |

1 x 95 |

1,6 |

18.2 |

912 |

962 |

4/0 (614/24) |

1 x 120 |

1,6 |

20.2 |

1115 |

1235 |

300 MCM(765/24) |

1 x 150 |

1,8 |

22.5 |

1440 |

1523 |

350 MCM(944/24) |

1 x 185 |

2,0 |

24.9 |

1776 |

1850 |

500MCM(1225/24) |

1 x 240 |

2,2 |

28.4 |

2304 |

2430 |