| Industrial Cables | |||

Industrial Cables-British Standard

318A to BS 6004(Formerly BS 7919)

Application and Description

318A to BS 6004(Formerly BS 7919) cables are designed to withstand severe external temperatures and will remain flexible at temperatures down to -40°C. Making them particularly suitable for outdoor applications and for use where flexibility is required at sub zero temperatures. At normal temperatures the cable is very flexible, offering some of the characteristics usually found in elastomeric cables.,

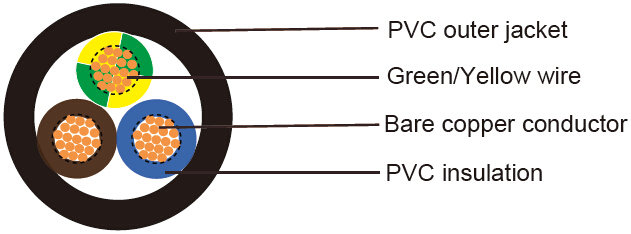

Cable Construction

-

Anealed copper conductor

Stranding to BS 6360 CL-5 or IEC 60228 CL-5

- PVC core insulation TI 4 to EN 50363-3-1(formerly BS 7655-3-1)

- Green/Yellow grounding (3 conductors and above)

- PVC outer jacket Type 10 to BS7655-4-2

- Yellow or blue

Core Identification

-

2Cores: Blue, Brown

3Cores: Green/Yellow, Blue, Brown

4Cores: Green/Yellow, Brown, Black, Grey or Green/Yellow, Blue, Brown, Black

-

5 Cores: Green/Yellow, Blue,Brown, Black, Grey

Technical Characteristics

-

Working voltage: 300/500 volts

Test voltage: 2000 volts

Flexing bending radius: 6xOverall diameter

Static bending radius: 4xOverall diameter

Flexing temperature: -5º C to +70º C

Static temperature: -40º C to +70º C

Short circuit temperature: +160º C

Flame retardant: IEC 60332.1

- Insulation resistance: 20 MΩxkm

Cable Parameter

| AWG (No of Strands/ Strand Diameter) |

No. of Cores x Nominal Cross Sectional Area #xmm² |

Nominal Thickness of Insulation mm |

Nominal Thickness of Sheath mm |

Nominal Overall Diameter mm |

Nominal Copper Weight kg/km | Nominal Weight kg/km |

| 3192A | ||||||

| 18(24/32) | 2x0.75 | 0.6 | 0.8 | 3.8x6.7 | 14.4 | 58 |

| 17(32/32) | 2x1.0 | 0.6 | 0.8 | 4.0x6.9 | 19 | 66 |

| 3182A | ||||||

| 20(16/32) | 2x0.50 | 0.6 | 0.8 | 6.1 | 9.6 | 46 |

| 18(24/32) | 2x0.75 | 0.6 | 0.8 | 6.4 | 14.4 | 57 |

| 17(32/32) | 2x1.0 | 0.6 | 0.8 | 6.8 | 19 | 65 |

| 16(30/30) | 2x1.5 | 0.7 | 0.8 | 7.6 | 29 | 87 |

| 14(50/30) | 2x2.5 | 0.8 | 1.0 | 9.2 | 48 | 134 |

| 12(56/28) | 2x4.0 | 0.8 | 1.1 | 10.5 | 77 | 174 |

| 3183A | ||||||

| 18(24/32) | 3x0.75 | 0.6 | 0.8 | 6.8 | 21.6 | 68 |

| 17(32/32) | 3x1.0 | 0.6 | 0.8 | 7.2 | 29 | 79 |

| AWG (No of Strands/ Strand Diameter) |

No. of Cores x Nominal Cross Sectional Area #xmm² |

Nominal Thickness of Insulation mm |

Nominal Thickness of Sheath mm |

Nominal Overall Diameter mm |

Nominal Copper Weight kg/km | Nominal Weight kg/km |

| 16(30/30) | 3x1.5 | 0.7 | 0.9 | 8.2 | 43 | 111 |

| 14(50/30) | 3x2.5 | 0.8 | 1.1 | 10.1 | 72 | 169 |

| 12(56/28) | 3x4.0 | 0.8 | 1.2 | 11.3 | 115 | 233 |

| 3184A | ||||||

| 18(24/32) | 4x0.75 | 0.6 | 0.8 | 7.4 | 29 | 84 |

| 17(32/32) | 4x1.0 | 0.6 | 0.9 | 8.0 | 38 | 101 |

| 16(30/30) | 4x1.5 | 0.7 | 1.0 | 9.2 | 58 | 142 |

| 14(50/30) | 4x2.5 | 0.8 | 1.1 | 11.2 | 96 | 211 |

| 12(56/28) | 4x4.0 | 0.8 | 1.2 | 12.5 | 154 | 292 |

| 3185A | ||||||

| 18(24/32) | 5x0.75 | 0.6 | 0.9 | 8.5 | 36 | 106 |

| 17(32/32) | 5x1.0 | 0.6 | 0.9 | 8.8 | 48 | 123 |

| 16(30/30) | 5x1.5 | 0.7 | 1.1 | 10.5 | 72 | 176 |

| 14(50/30) | 5x2.5 | 0.8 | 1.2 | 12.4 | 120 | 262 |

| 12(56/28) | 5x4.0 | 0.8 | 1.4 | 13.7 | 192 | 369 |