| Motor Connecting Cables | |||

![]() 9YSLCY-JB

9YSLCY-JB

Application

These cables are double shielded, large gauge size, UL/CSA/CE approved

PVC motor supply cable. Polypropylene insulation over very fine stranded

copper provides a low-loss transfer of power, excellent low capacitance

performance and superior flexibility when compared to conventional

PVC cables. The applications include frequency converters, motor

runs, connections with high electromagnetic interference. Found in the

automotive, paper and food industry, environmental technology, packaging

industry, machine tools and handling equipment. The overall foil and braid

shield offer excellent protection against electromagnetic and electrical interferences. For medium mechanical

stresses found indoors in dry, moist and wet areas.

Standard and Approval

UL AWM 2570 or 20886, VW-1; CSA AWM I/II A/B, FT-1; UL/CSA rated 1kV 80 Deg C.; VDE 0250, VDE

0207, VDE 0276; EMC to EN 55011; EMC to VDE-0875 part-11; CE Low Voltage Directive 73/23/EEC and

93/68/EEC, ROHS compliant

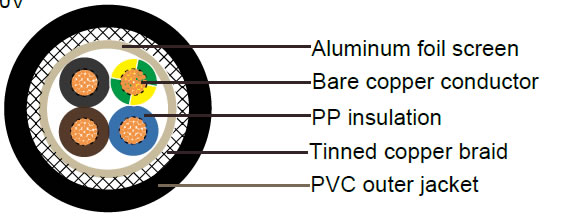

Cable construction

- Stranded bare copper conductor according to DIN VDE 0295, IEC60228 cl. 5

- Polypropylene (PP) insulation

- Colours according to HD 308 S2(VDE 0293- 308)

- Special aluminum foil screening

- Tinned copper braiding, coverage approx. 85%

- Transparent PVC sheath made of PVC compound YM2 acc. VDE 0207 -5, leadfree, flame retardant & selfextinguishing

Technical Characteristics

- Working voltage: IEC 600/1000V / UL & CSA 1000V

- Test voltage: 4000 volts

- Minimum bending radius: 15 x Ø

- Flexing temperature: -5º C to +80º C

- Fixed installation temperature: - 40º C to +80º C

- Flame retardant: IEC 60332.1 VW-1

- Insulation resistance: >20 GΩ x km

Cable Parameter

AWG |

No. of Cores x |

Nominal Overall |

Copper Weight kg / km |

Cable Weight kg / km |

16(30/30) |

4 G 1.5 |

10.5 |

87 |

230 |

14(50/30) |

4 G 2.5 |

11.8 |

133 |

300 |

12(56/28) |

4 G 4 |

13.3 |

213 |

485 |

10(84/28) |

4 G 6 |

14.9 |

298 |

630 |

8(80/26) |

4 G 10 |

17.7 |

460 |

860 |

6(128/26) |

4 G 16 |

21.5 |

707 |

1290 |

4(200/26) |

4 G 25 |

26.3 |

1100 |

1860 |

2(280/26) |

4 G 35 |

29.7 |

1542 |

2610 |

1(400/26) |

4 G 50 |

34.1 |

2206 |

2950 |

2/0(356/24) |

4 G 95 |

40.9 |

3002 |

3950 |

3/0(485/24) |

4 G 95 |

45.4 |

4004 |

5300 |

4/0(614/24) |

4 G 120 |

49.8 |

5108 |

6600 |

300 MCM (765/24) |

4 G 150 |

56.1 |

6225 |

7043 |

350 MCM (944/24) |

4 G 185 |

61.4 |

7568 |

8384 |

500 MCM |

4 G 240 |

67.9 |

9940 |

12150 |